Forbo

Forbo high efficiency flat belts and conveyor and processing belts often play a pivotal role providing innovative concepts in production, material flow and logistics.

Leading manufacturing companies all over the world count on Forbo Siegling specialists as competent partners in developing groundbreaking solutions in power transmission, conveying and manufacturing.

Conveyor belts and processing belts – Siegling Transilon

Siegling Transilon conveyor belts and processing belts for speeding the flow of goods and for economic processing in the light materials handling industry.

Siegling Transilon conveyor belts and processing belts for speeding the flow of goods and for economic processing in the light materials handling industry.

The standard Siegling Transilon construction consists of polyester fabric as tension member with synthetic or elastomer coatings. Siegling Transilon is used successfully in industrial, commercial and service companies worldwide. The standard product range includes over 120 various conveyor belt types and constructions for the most diverse of application requirements.

Power transmission belts – Flat belts

We have developed the Siegling Extremultus power transmission belt range in close co-operation with users and OEMs. As a result, it can offer a market- driven range of types that can handle all sorts of power transmission in every industry.

Siegling Extremultus power transmission belts are durable, extremely tough, elastic, absorb vibrations and shocks and can be used at belt velocities of up to 100 m/s. Compared with other power transmission belts, they are easy to handle, extremely efficient and have a high level of synchronisation accuracy. Apart from traditional pulleys, they can easily handle bevel and cone drives and drive several shafts, even in different rotational directions.

Siegling Prolink Modular Belts

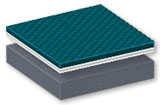

Modular belts are robust and durable. They handle conveying and processing tasks, not possible with conventional belting material. They can be made endless on the conveyor; if damage occurs individual modules can be quickly exchanged. This minimizes down times. Different lengths and widths are possible. Functional modules can be inserted at any time, so even belt properties can be changed whenever required.

Modular belts are robust and durable. They handle conveying and processing tasks, not possible with conventional belting material. They can be made endless on the conveyor; if damage occurs individual modules can be quickly exchanged. This minimizes down times. Different lengths and widths are possible. Functional modules can be inserted at any time, so even belt properties can be changed whenever required.

Siegling Prolink can offer various different module designs, materials and accessories, all combinable with one another. So Siegling Prolink modular belts can be customised to suit the conveying or production job in question.

High-Efficiency Timing Belts – Siegling Proposition

As form-fit power transmission and conveying elements Siegling Proposition timing belts round off the family of tried and tested Siegling Transilon conveyor and processing belts. Our extensive experience in the field of light materials handling is our guarantee for excellent product quality and practice-oriented service.

The Siegling Proposition product range includes all common timing belt pitches for standard conveying and handling operations. Available open or welded endless, the belt widths available have been selected to match standard toothed pulley widths.

The Siegling Proposition product range includes all common timing belt pitches for standard conveying and handling operations. Available open or welded endless, the belt widths available have been selected to match standard toothed pulley widths.

- T Pitch

- AT Pitch

- XL, L, H, XH-Pitch

- HTD Pitch

- Wide belts

Innovative Belting for Metalworking

If manufacturing and supplying product just in time is vital and downtime is counted in minutes, Forbo Siegling is the perfect choice.

The requirements in many areas of metalworking are just as varied as the belt solutions themselves are. Forbo’s range of fabric-based conveyor and processing belts, as well as plastic modular belts, offers the right belt for each application.

Forbo Siegling offers 5 product groups to make metalworking efficient. Different belting products can be used in many steps of the process.

|

|

|

|

|

| siegling transilon | transtex belting | siegling prolink | siegling proposition | siegling extremultus |

|

|

|

|

|

AMP MISER™ 2.0 Next Generation Conveyor Belts

Amp Miser™ 2.0 is the second generation of energy-saving conveyor belts from Forbo Movement Systems. The new belts have drastically lower friction coefficients. Therefore, they are safe to use – even on galvanised slider beds – and generate energy efficiencies of up to 50 per cent.

Amp Miser™ 2.0 is the second generation of energy-saving conveyor belts from Forbo Movement Systems. The new belts have drastically lower friction coefficients. Therefore, they are safe to use – even on galvanised slider beds – and generate energy efficiencies of up to 50 per cent.

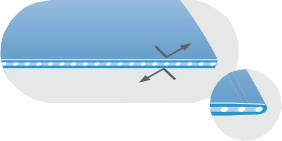

The Amp Miser™ 2.0 belts feature cutting-edge tension members made of polyester and enhanced Texglide™ technology. As a result, the friction between the underside of the belt and the slider bed (therefore the energy consumption) are much lower. Compared with conveyor belts that have standard underside fabrics, up to 50 per cent of the energy required for power transmission can be saved in applications with long conveyors and heavy loads.

The Texglide™ finish on the underside fabric is an integral component of the Amp Miser™ belts and doesn’t rub off. The low friction coefficient is permanent. Second generation Amp Miser™ types are therefore ideal for use on galvanised slider beds.

PROSAN™ 2.0 Hygienic and Safe All the Way

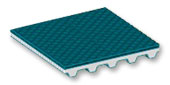

Prosan’s two-sided coating reduces the chance of the carcass being contaminated by oil, grease, moisture or other contaminants. The Prosan™ Frayfree (FF) belt has virtually lint-free edges. Optional Smartseal belt-edge sealing provides an encapsulated design making it suitable for the toughest contaminating environments.

Protected belt carcass for unique hygienic properties

Protected belt carcass for unique hygienic properties

The two-sided coating reduces the chance of the carcass being contaminated by oil, grease, moisture or other contaminants. The Prosan™ Frayfree (FF) belt has virtually lint-free edges.

Furthermore, optional Smartseal belt-edge sealing provides an encapsulated design making it suitable for the toughest contaminating environments.

Low friction coefficient for economical operation

Low friction coefficient for economical operation

Patent pending new Broken Twill (BT) underside pattern with a particularly low coefficient of friction on the slider bed and an easy to clean design.

Small drum diameters down to ø 10 mm

Prosan™ belts have very flexible tension members. Despite the polyurethane coating on both sides, small drum diameters down to 10 mm are still possible, offering an effective alternative to single-sided coated belts that are relatively less hygienic for many uses.