Piab

Piab

Piab is a global leader in industrial vacuum technology with several innovative products and solutions to improve productivity in automation.

Piab's core technologies:

- Generate vacuum based on compressed air

- Handling parts with suction cups/suction grippers

- Optimized products proven to save energy

Suction Cups & Grippers

Suction Cups & Grippers

Using suction cups is a lifting technique of many possibilities. You can, for example, handle board materials or concrete slabs, open bags, pick electronic components, label and hold objects. But different applications need different requirements. Piab offers one of the market’s widest ranges of suction cups so that each application will have its own solution.

suction cups & grippers

Vacuum Pumps/Generators

COAX® technology Piab's patent technology platform is an offshoot of the multistage technology. COAX® ensures excellent performance at both low and high feed pressures – ideal for situations where compressed air lines deliver air at low or fluctuating pressures. Pumps based on the COAX® technology can operate within the range of 25 to 87 psi.

Piab vacuum pumps are of the multi-stage ejector type – a technology patented by Piab in 1973. These vacuum pumps were developed to provide extra vacuum flow in combination with deep maximum vacuum levels while keeping energy consumption at a minimum.

Piab pumps have no moving parts that vibrate or wear out – important features that contribute heavily to outstanding operational reliability and a pleasant, noise-free working environment.

vacuum pumps & generators

Vacuum Cartridges/Integration

COAX® is an advanced solution for creating vacuum with compressed air. Based on Piab’s multistage technology, COAX® cartridges are smaller, more efficient and more reliable than conventional ejectors, which allows for the design of a flexible, modular and efficient vacuum system. A vacuum system based on COAX® technology can provide you with three times more vacuum flow than conventional systems, allowing you to increase speed with high reliability, while reducing energy consumption.

COAX® is an advanced solution for creating vacuum with compressed air. Based on Piab’s multistage technology, COAX® cartridges are smaller, more efficient and more reliable than conventional ejectors, which allows for the design of a flexible, modular and efficient vacuum system. A vacuum system based on COAX® technology can provide you with three times more vacuum flow than conventional systems, allowing you to increase speed with high reliability, while reducing energy consumption.

vacuum cartridges / integration

Combined Pump & Gripper

Combined Pump & Gripper

Piab VGS™ – A product design where high quality DURAFLEX® suction cups are integrated with vacuum cartridges based on the patented COAX® technology. The “vacuum gripper” makes selection, sizing and installation of a vacuum system easier. With a VGS™ you will enjoy the benefits of a more cost-efficient and reliable vacuum system.

XLF Extra Large Flat suction cups

Suitable for handling large and heavy sheets, such as glass and metal, with a flat or slightly concave surface, the XLF line of suction cups are available in four different diameter sizes 150 mm, 200 mm, 250 mm and 300 mm. All sizes are similarly designed with an aluminum plate molded into the durable and long lasting 60° Shore Nitrile-PVC rubber. The cups are ideal for sensitive surfaces as the soft material will not chip or damage the material being handled. Friction pattern increases safety and capability to handle tilted or standing glass/metal sheets. Double lip design increases safety against over-load or tear on the outer lip. Auxiliary port, suitable for vacuum sensing or efficient blow-off/release.

- Suitable for handling large and heavy sheets, such as glass and metal, with a flat or slightly concave surface.

- Friction pattern increases safety and capabillity to handle tilted or standing glass/metal sheets.

- Double lip design increases safety against over-load or tear on the outer lip.

- Durable and abrasive resistant material reduces the risk for marks.

- Flat mounting plate facilitates customized mounting interfaces.

- Auxiliary port, suitable for vacuum sensing or efficient blow-off/release

XLF Extra Large Flat suction cups >

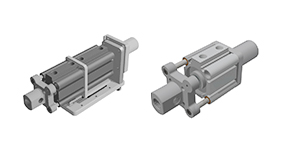

Double capacity ejector fits popular format

Piab is introducing a complement to its range of Value Line® vacuum ejectors. The new aluminum block mounted ejector is dimensioned to emulate a popular ejector format, making it easy to install into many existing systems. Offering improved performance and more energy-efficient operation, the ejector is a cost-effective and easy-to-install alternative for operators of basic automated vacuum systems.

Piab is introducing a complement to its range of Value Line® vacuum ejectors. The new aluminum block mounted ejector is dimensioned to emulate a popular ejector format, making it easy to install into many existing systems. Offering improved performance and more energy-efficient operation, the ejector is a cost-effective and easy-to-install alternative for operators of basic automated vacuum systems.

The capacity of the new ejector is twice that of our inline ejectors. But the really clever advantage is that it is designed to slot nicely into existing systems, where it will offer better performance and more energy-efficient operation for the same price as competing ejectors.

- Ejector with improved vacuum performance compared to corresponding size conventional single-stage ejector.

- Ejector stage without flap valve gives high reliability in dirty and dusty environments.

- Light weight body.

- Integrated push-in fittings or thread connection for quick and low cost installation.

- Available in “Inline”, “T-design” or aluminum block version.

- The T-design is suitable if exhaust air needs to be piped away.

- The VL206 1/8” block version is an easy-to-install alternative, targeting operators of basic automated vacuum systems.

Rectangular Suction Cups

Rectangular Suction Cups

The RB20x40P cup was developed, by Piab, specifically for handling flow-packed bars of sweets, but it can of course be used for any small, rectangular flow pack packages. It provides safe and secure handling without damaging either the packaging or its content.

Made in a specially developed material that features the elasticity of rubber and wear resistance of polyurethane, DURAFLEX® suction cups are particularly suitable for handling uneven and porous surfaces. Designed with a single bellows, the cup has a low overall height, making it easy to fit into space-restricted areas. Additionally, in order to provide the correct orientation when installed, the RB20x40P is available with two alternative fittings.

piCOMPACT®23 is now available with a range of unique and patented added features

Improved and intelligent blow-off functions, a split unit design, and a self-adhesion control feature are a few of the new added extras on offer in Piab’s premium piCOMPACT®23 vacuum generator platform. This impressive range of proprietary and patented added features, which also includes IO-Link communication, has the potential to provide optimal vacuum generation for every application.

Improved and intelligent blow-off functions, a split unit design, and a self-adhesion control feature are a few of the new added extras on offer in Piab’s premium piCOMPACT®23 vacuum generator platform. This impressive range of proprietary and patented added features, which also includes IO-Link communication, has the potential to provide optimal vacuum generation for every application.

The compact, all-in-one ejector platform is stackable; up to four units can share the same manifold and pneumatic connections, such as a common feed pressure and exhaust. The option to utilize a split unit design and separate the ejector from the control unit offers added flexibility, particularly where space is limited or for minimizing the weight carried by robot arms.

The integrated and patented valve of Piab’s proprietary Blow-off feature ensures more efficient and energy-saving blow-off, enabling faster production cycles. It can also be used to float suction cups whilst positioning them in, for instance, ergonomic lifting aids, or simply to clean suction cups in dusty environments.

A patented Intelligent Blow-off (IBO) feature automatically switches off the blow-off when the vacuum is gone, offering further energy-saving. This feature is also compatible with the bi-stable (latching) on/off valves that can be used in systems prone to emergency stops or those handling expensive objects.

Vaculex VL Heavy-Duty Vacuum Lifter

Vaculex is available in six lift tube sizes, between 100 mm and 200 mm, with five different vacuum pumps and many accessories and suction feet for a virtually infinite number of combinations. Normally, Vaculex is driven by an electric vacuum pump for best performance and flexibility but we can also provide pneumatic vacuum pumps if required.

Lift almost everything

With a vacuum tube lifter you can lift boxes, sacks, drums, sheet metal, computers, crates, barrels, TVs and much more – depending on equipment and accessories.

The design consists of a pump, vacuum hose, lift tube, control unit and finally a suction foot or possibly a gripping tool which is adapted to your needs.

Good ergonomics is good economics

Repeated lifts do not have to be heavy to be both dangerous and costly. Most often, vacuum tube lifters lead to an increased work rate and better productivity.

Costs for extended periods of sick leave are reduced and rehabilitation periods are avoided. Our tube lifters minimize that type of problem and also reduce the risk of accidents that can injure the user as well as damage the goods.

Kenos KCS Vauum Gripper

Flexible, cobot friendly gripper

Flexible, cobot friendly gripper

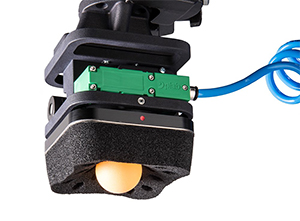

The KCS is a new complete vacuum gripper from Piab based on ejector technology, suitable for collaborative robots, with its lightweight and smooth design. The modular KCS will give an excellent grip on almost any type of surface, and therefore a unique level of flexibility when it comes to picking up objects. This wide range of use thereby eliminates the need for retooling.

Combining Piab's proprietary air-driven COAX® technology for highly efficient vacuum ejection with an easily replaceable technical foam that molds itself around any surface or shape, the Kenos® KCS gripper can be used to safely grip, lift and handle any object.

- The KCS (Kenos® collaborative small) gripping system is equipped with integrated COAX® SX cartridges.

- The quick change system of KCS allows the gripper to move from one application to another very quickly.

- The COAX®SX cartridges- providing high performance even at low or fluctuating feed pressures. The KCS can be equipped with 1 or 2 COAX®SX cartridges.

- The KCS is equipped with a flow restrictor suitable for handling different sized sealed or leaking objects with the same lifting device even if the total foam area is not covered, the KCS will still maintain enough vacuum level to lift the object.

Learn more about KCS Vacuum Grippers

piLIFT® SMART

piLIFT® SMART is the first vacuum lifter ever that meets the needs of industry 4.0. The usability, flexibility and data management capability put it in a category of its own. Combining the best of vacuum lifting technology with 76% less energy consumption, minimal sound levels and smart data features, the quick and intuitive piLIFT SMART is truly a leap forward. piLIFT® SMART brings the latest technology to enable both operator and operation to obtain live information on performance and status via a web-based platform.

piLIFT® SMART is the first vacuum lifter ever that meets the needs of industry 4.0. The usability, flexibility and data management capability put it in a category of its own. Combining the best of vacuum lifting technology with 76% less energy consumption, minimal sound levels and smart data features, the quick and intuitive piLIFT SMART is truly a leap forward. piLIFT® SMART brings the latest technology to enable both operator and operation to obtain live information on performance and status via a web-based platform.

The weight of the lifted object will be displayed on the piLIFT® SMART screen which will help the operator to distinguish and identify loads as well as quality assure incoming or outgoing products. No handling device has been more ergonomic, intuitive and easy to learn. Not only have we considered the operator, piLIFT® SMART offers increased benefits of operation. An improvement that will benefit users, operations and environment.

Learn more about piLIFT® SMART

piCOBOT® – Piab’s latest productivity promoter

piCOBOT® is a cleverly equipped end-of-arm (EOAT) vacuum tool designed specifically for the cobot market. Featuring the company's signature vacuum technology, enabling improved efficiency, productivity and working environments, piCOBOT® offers industry certified plug-and-play extensions to the latest collaborative robots, so called cobots.

piCOBOT® is a cleverly equipped end-of-arm (EOAT) vacuum tool designed specifically for the cobot market. Featuring the company's signature vacuum technology, enabling improved efficiency, productivity and working environments, piCOBOT® offers industry certified plug-and-play extensions to the latest collaborative robots, so called cobots.

Offered as a development kit, piCOBOT® comprises a vacuum pump unit, a gripper unit and two suction cups. The standard kit includes four different sets of suction cup models suitable for a variety of tasks, but customers can also choose freely from the company's extensive range of suction cups for more tailored solutions.

Certified by Universal Robots, piCOBOT® builds on the idea of safe and flexible human-robot workplace interaction, found to be much more productive than either of them working on their own. Soft design lines guarantee that no one is injured if colliding with piCOBOT®. With a piCOBOT® unique URCaps installation, programming time is decreased to a minimum for the customer.

Designed for maximum flexibility and reach, piCOBOT®'s 3.87-5.71"wide and +/-15 degree tiltable gripper arms can be fitted with two suction cups. Alternatively, the gripper can be replaced by a single suction cup mount directly on the piCOBOT® pump unit. For optional single or double object picking, dedicated sense valves ensure safe operation regardless of mode.

While a compact format and low build height of 2.71" allow use in space-restricted areas, the low weight of Piab's solution offers a great advantage compared with similar competing systems.

piCOBOT® weighs only 18 oz. and the gripper only adds another 7.40 oz. This provides maximum payload capacity for the cobot. Strong for its size, piCOBOT® is able to lift objects weighing up to 15.5 lbs..

End-of-Arm Tooling Line

Piab is introducing a new line of robotic End-Of-Arm Tooling (EOAT) products, enabling customers to build automated systems that perfectly fit their specific applications. Piab’s complete set of off-the-shelf standard components can be used to solve the real automation challenges facing manufacturers. Made up of several different families of components, the new EOAT line offers standard products in a broad range of sizes and dimensions, resulting in a modular automation technology set comprising an impressive 600 different pieces of equipment.

|

Gripper arms extend and mount suction cups to mounting clamps.

|

|

Manifolds, tubing, and fittings used to connect pneumatic vacuum or compressed air components.

|

|

A big variety of jaws (saw tooth, knurled, padded) and with or without sensors, to be able to handle various sprues and parts.

|

A selection of Piab's wide range of suction cups for various applications.

|

|

piCOMPACT® is an ejector family with integrated controls, so called compact or ”all-in-one” ejector unit. It is a stackable platform with the possibility to mount several units in the same manifold and have common pneumatic and electrical connections. With the state-of-the-art vacuum engine, COAX®, the product is outstanding. By working at low feed pressure and maximizing the utilization rate of the compressed air, the COAX® ejectors reduce energy consumption for manufacturers while increasing productivity and reliability.

piCOMPACT® is an ejector family with integrated controls, so called compact or ”all-in-one” ejector unit. It is a stackable platform with the possibility to mount several units in the same manifold and have common pneumatic and electrical connections. With the state-of-the-art vacuum engine, COAX®, the product is outstanding. By working at low feed pressure and maximizing the utilization rate of the compressed air, the COAX® ejectors reduce energy consumption for manufacturers while increasing productivity and reliability.