AHP is Now a Parker Certified Composite Hose Assembly Fabricator - with an extensive inventory and technicians ready to handle your rush orders!

Parker

Parker

Parker offers the largest selection of hoses plus more fitting sizes than any other manufacturer. You’ll find a wide variety of hoses including braided, spiral and multi-purpose, and more than 4,500 Parkrimp fittings. Parker products have been designed, tested and approved to meet and exceed global standards. The right product is available for your application, including hose that features a variety of abrasion resistant cover choices, flexibility, a wide range of media compatibility and more – characteristics that make Parker the hose supplier of choice for customers that demand the most from their equipment.

Twinhammer™ Bonded Air/Water Jackhammer Hose Assemblies

Parker Series 7084 Twinhammer Hose is the FIRST factory-assembled dual hose system! Th is hose is designed with dual air and water lines to be an ideal solution for silica dust suppression in pneumatic jackhammer applications.

These hoses can help customers with safety standard compliance designated by OSHA.

learn more...

GlobalCore Hose

GlobalCore Hose

Together, we can reduce your inventory with a cohesive family of hoses and fittings.

You know Parker as the global leader in providing unprecedented performance and value for hydraulic systems with high-pressure applications. With our GlobalCore solution, you can simplify your part number complexity with a globally available, cohesive product line of high-performance constant working pressure hoses. Providing a simple solution of robust hydraulic hoses designed to endure the tough conditions where work gets done, GlobalCore is the future that OEMs and end users around the world have been asking for.

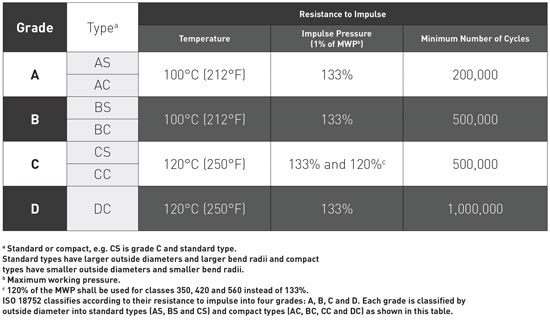

Designed, built, and tested to the ISO 18752 specification, GlobalCore reduces engineering and service complexity by providing the first comprehensive product family across the most commonly used constant working pressure classes.

Composite Hose

Composite Hose from Parker Offers Lasting Value for Petrochemical Applications

Parker composite hose is a unique alternative to traditional rubber and metal hose. It provides lighter weight, superior flexibility, minimal force to bend and unparalleled kink and vibration resistance, making it suitable for a wide array of petrochemical fluids in loading/unloading,  processing, transfer and transport applications.

processing, transfer and transport applications.

Parker composite hose assembly systems-using a new generation of hose constructions, innovative dry seal coupling technology and Parker crimping equipment.

- Save time and expense

- Quick fabrication

- Easy installation

- Superior long-lasting performance

Compact Spiral Hydraulic Hose

Compared with conventional spiral hose, Parker’s Compact SpiralTM 787TC/797TC hose offers measurably greater advantages in routing and installation, product size and weight, inventory savings and much more. A world’s first, this development is the most significant advancement in hydraulic hose since the introduction of Parker’s No-SkiveTM technology more than 25 years ago.

Compared with conventional spiral hose, Parker’s Compact SpiralTM 787TC/797TC hose offers measurably greater advantages in routing and installation, product size and weight, inventory savings and much more. A world’s first, this development is the most significant advancement in hydraulic hose since the introduction of Parker’s No-SkiveTM technology more than 25 years ago.

Compact Spiral was developed in concurrence with the industry trend toward highpressure hose manufactured to meet ISO 18752 performance specifications. This innovative flexible compact spiral hydraulic hose provides a notably long service life, meeting twice the number of required test cycles for use in both stationary and mobile industrial machinery in a wide range of applications, including General Industry Manufacturing, Construction, Defense, Oil and Gas.

This new compact hose product offers high-end hose performance at 5,000 or 6,000 psi.

- Smaller outside diameter and tighter bend radius

- Improved productivity because your hose is easier to route and install which saves valuable labor time and effort

- The option to use larger size hose for better flow characteristics in tight space applications

- This new hose weighs up to 26% less than standard spiral hose reducing shipping and packaging costs.

Download Compact Spiral Hydraulic Hose Brochure

Parker offers a wide selection of hoses:

Parker offers a wide selection of hoses:

- Compressed Air hose

- Hydraulic-Jack Hose

- Braided Hydraulic hose

- Liquefied Petroleum Gas

- Refrigerant

- Constant Working Pressure

Mechanical Crimp Connection

Mechanical Crimp Connection for piping or tube systems saves the time and costs of welding

For today’s piping or tube assemblies, Parker’s Mechanical Crimp Connection (MCC) eliminates time-consuming, costly welding – and ensures reliable, leak-free performance. MCC consists of a simple hydraulic assembly tool, specially designed bite ring and adapters. The bite ring attaches to the pipe or tube and secures the adapter. Internal seals in the MCC adapter ensure a leak-free connection and protect against ingression mechanical crimping of adapters to tube or piping.

- Eliminates time and costs of welding and post-weld processes

- Quicker, easier assembly promotes increased equipment uptime

- Inherently safe, clean process

- Internal sealing components ensure leak-free performance

- 6000 psi/415 bar pressure rating at 4:1 design factor

Horizontal Crimper

Parker’s TH8-380 production crimper is designed to withstand the rigors of high volume production hose assembly manufacturing. The electronic controls come preloaded with Parker hose part numbers and crimp specifications to make hose selection quickly and easily. The greaseless die design of the TH8-380 requires less maintenance and provides a cleaner work environment due to the revolutionary slide bearing technology. The TH8-380 sets a new standard for high quality and cost effective production crimpers. This production crimper is user friendly and built with a solid construction in order to provide a long service life.

Featured Products

| Parker E-Z Form Hose | Pre-Configured Hose Assemblies | Part Tracking System |

| 83FR DuraGard | Ultralite Superbraid | Twinhammer Bonded Hose |

Air Hydro Power is a Parker Hose distributor in Kentucky, Alabama, and Mississippi. We offer free product evaluations and technical support to help our customers solve their applications.

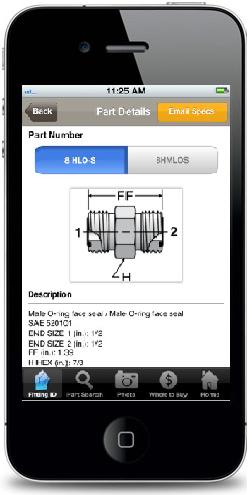

Parker fitting identification and locator for finding the correct part number of many of the Parker fittings you seek. A handy distributor locator and CAD models are also included.

Parker fitting identification and locator for finding the correct part number of many of the Parker fittings you seek. A handy distributor locator and CAD models are also included.