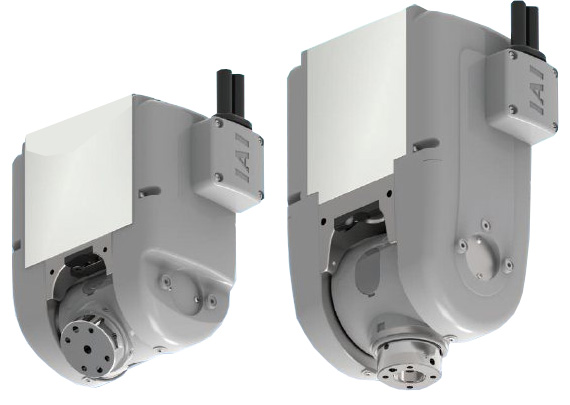

WU Series - 2-Axis Wrist Units

IAI's Unique WU Series Wrist Unit design makes it light weight and compact in size.

IAI's Unique WU Series Wrist Unit design makes it light weight and compact in size.

Equipped with a battery-less absolute encoder as standard, the WU Series is a low cost alternative, compared to 6-axis articulated robots making it ideal for reducing the cost of equipment.

Diagonal approaches and tip swiveling can now be performed with minimum required axis configuration which until now required a vertically articulated robot.

- Unique design makes the parts light and compact

- Ideal for reducing the cost of equipment

- Orthogonal axes and interpolation commands are possible

IK Series Multi-Axis Cartesian System

The competitively priced ROBO Cylinder IK Series is the multi-axes solution to your automation needs. In addition to easy set-up and simple software programming, IAI's high-quality electric actuators are energy efficient and will dramatically reduce your energy bills.

The competitively priced ROBO Cylinder IK Series is the multi-axes solution to your automation needs. In addition to easy set-up and simple software programming, IAI's high-quality electric actuators are energy efficient and will dramatically reduce your energy bills.

The ROBO Cylinder IK Series multi-axes kit includes everything needed for fast and easy assembly. The available configurations have been greatly expanded, allowing the ideal selection to suit your needs from 396 options. The ROBO Cylinder® equipped as standard with a Battery-less Absolute Encoder has been added to the "IK Series".

No battery maintenance is required since there is no battery. Homing operation is not required at startup or after emergency stop or malfunction. This reduces your operation time, resulting in reduced production costs.

Compatible with PowerCON® which is equipped with a high-output driver. The maximum speed has been increased with the use of PowerCON®. This can reduce cycle time and help improve productivity.

High Speed Actuators

Shortenting production equipment cycle times

Shortenting production equipment cycle times

By adopting a high-speed actuator, you will be able to shorten your production equipment cycle time, improving your equipment's production capacity.

IAl's lineup of high-speed actuators come in four driving systems: ball screw drive, ball screw nut rotating drive, belt drive, and linear motor type. There is a total of 69 types in 12 series with maximum speed of over 2,000mm/s. you can choose the most suitable one to meet your needs.

watch high speed actuator video

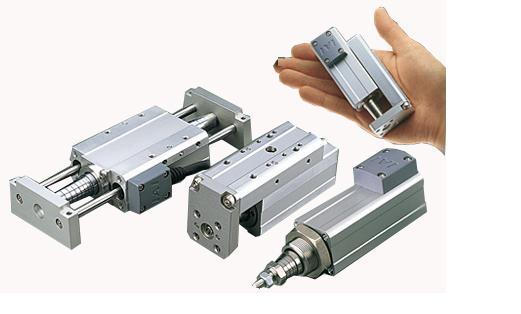

Mini ROBO Cylinders

Shaped like an air cylinder and easy to use the Mini-ROBO Cylinder has achieved smaller size with significantly reduced overall length, width and height which are comparable to air cylinders. Systems that could only use air cylinders due to sizing constraints can now use Mini ROBO Cylinders to improve performance.

Shaped like an air cylinder and easy to use the Mini-ROBO Cylinder has achieved smaller size with significantly reduced overall length, width and height which are comparable to air cylinders. Systems that could only use air cylinders due to sizing constraints can now use Mini ROBO Cylinders to improve performance.

If you have been using air cylinders and are unhappy with the long time needed to change the positions or want to stop the actuator between two points, you can adopt a ROBO Cylinder system and continue it with PSEP/ASEP controller. Users who are comfortable with the handling of pneumatic systems are now able to switch to ROBO Cylinder effortlessly.

- Slider type

Rod type - Table top

- Linear servo type

- Guided and Non-guided

ERC3 ROBO Cylinder with built-in controller

Transform your factory with the efficiency-improving, space-saving ERC3 ROBO Cylinder®.

Transform your factory with the efficiency-improving, space-saving ERC3 ROBO Cylinder®.

Because the controller is built-in, no additional controller is required. The result is a smaller footprint of the control panel. Also teaching can be performed near the actuator because the controller is built-in.

The ERC3 supports wide-ranging operations with 30% longer strokes and payloads and speeds have been increased by 1.5 times over conventional model. It’s the most affordable in the ROBO Cylinder series!

IAI - Motorized Vertical Grippers

IAI's Vertical grippers are available in two types, including the slider type that comes with a guide to achieve excellent rigidity, and the lever type whose levers open by 180 degrees for easy gripping of the work part.

Slider Type and Lever Type Grippers

Slider Type and Lever Type Grippers

Vertical grippers are available in two types, including the slider type that comes with a guide to achieve excellent rigidity, and the lever type whose levers open by 180 degrees for easy gripping of the work part.

Multi-point Positioning, Adjustable Gripping Force

Up to 512 positioning points are supported via servo control, and the force with which to grip the work part is adjustable. This makes it possible to adjust the finger opening/closing width and grip easy-to-deform work parts.

Highly Rigid, Accurate Guide and Driving Part

The slider type comes with a highly rigid linear guide to demonstrate high moment rigidity. Thanks to its backlash eliminating mechanism, the guide is subject to less displacement upon positioning. The driving part adopts a geared structure (worm + helical gears) to achieve high rigidity and excellent response.

Self-locking Mechanism to Prevent Parts Dropping upon Power Off

The self-locking mechanism prevents the work part from dropping when the power is turned off or an emergency stop is actuated. The slider and levers can be opened with ease using an Allen wrench.

* The actuator cannot be kept pushing the work part.

Ultra-compact Slider Type

Ultra-compact Slider Type

High gripping force in a compact body (gripping force: 10 N). One of the smallest actuators in the industry with a cross section area of 22 x 15 mm.