Universal Robots

Universal Robots

Air Hydro Power is a certified reseller of the Universal Robots e-Series robots. No other automation solutions provider in Kentucky or Alabama has a Universal Robotics specialist on staff. In addition to being the number one solutions provider for the UR e-Series, Air Hydro Power is also a certified product specialist in end-effectors that work with the UR robots. Air Hydro Power offers on-site demos or demonstrations at any of our 13 locations throughout Kentucky and Alabama.

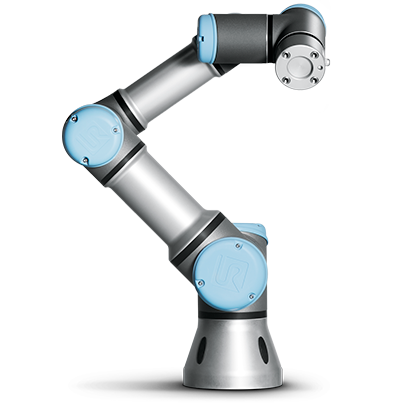

Universal Robots are flexible, lightweight and user-friendly 6-axis industrial robots. They are developed specially for small and medium enterprises, which have the need for flexible and effective automation that can provide them fast return of investments.  The robots are easy to move around and do not require sturdy bases due to their lightweight structure. Safety fencing is not needed.

The robots are easy to move around and do not require sturdy bases due to their lightweight structure. Safety fencing is not needed.

URe Series

URe Series

With the e-Series you can unpack, mount and program your cobot in less than an hour with no special electrical requirements.

Built with the future in mind, theUR e-Series is designed to grow in capability alongside your business, a spring board to improved product quality and productivity, so you will always be able to stay ahead of competition. Equipped with intuitive programming, versatile use and an almost endless list of opportunities for add-ons, the e-Series is able to complement production regardless of your industry, company size or product nature.

|

Learn more about UR e-Series Robots

LEARN THE THRUTH ABOUT THE 5 MYTHS ABOUT ROBOTS

APPLICATION CASE STUDIES

UR3

UR3

The ultra flexible Universal Robots UR3 delivers high-precision accuracy for smaller production environments. The UR3 can modulate payloads of up to 3 kg (6.6 lbs).

Designed for shorter reach environments, the UR3 has a reach radius of 500 mm (19.7 in) – allowing it to be deployed in tight spaces and add value to virtually any production environment. The UR3 also has InfiniteSpin™ on the last joint, allowing you to use it for screwing tasks without having to add additional devices.

UR5

UR5

The UR5 is a 6-axis robot arm with a working radius of 850 mm / 33.5 in and a payload of 5 kg (11 lbs). With a weight of 18 kilos the UR5 can easily be moved around in the production and used in many different instances.

The UR robots can work collaboratively right alongside employees due to built-in force-sensing causing the robots to automatically stop operating when they encounter obstacles in their route.The robot can be programmed to operate in reduced mode when a person enters the work zone.

UR10

UR10

The UR10 is a 6-axis robot arm with a working radius of 1300 mm / 51.2 in, and a payload of 10 kg (22 lbs). With a weight of 25 kilos the UR-10 can easily be moved around in the production and used in many different instances. With the user friendly software, the robotic arms can be easily and quickly programmed to perform new tasks.

Robot Guidance with SICK Inspector

Create a vision guided robot application in minutes with SICK 2D vision!

The SICK Inspector URCap software provides an easy integration between the Universal Robot and a SICK Inspector PIM60 2D vision sensor.

View the live image from the sensor, calibrate and align the sensor, choose reference object and get pick-point positions, all from the Universal Robot's teach pendant.

In addition to outputting pick-points in the robot’s coordinate system, the Inspector PIM60 enables inspection and measurement tasks for pass/fail-criteria or trending.

Screwdriving

Screwdriving- Pick and Place

- CNC

- Packaging and Palletizing

- Quality Inspection

- Lab Analysis and Testing

- Machine Tending